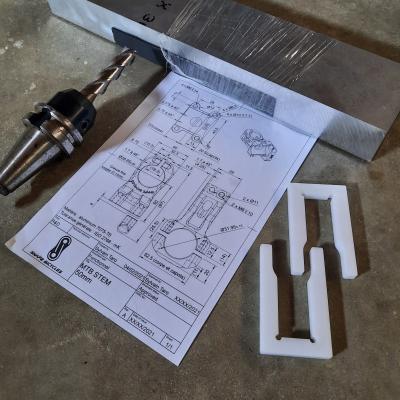

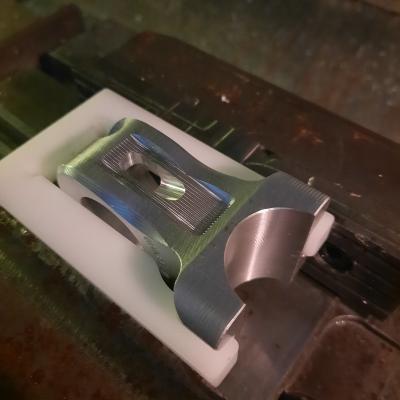

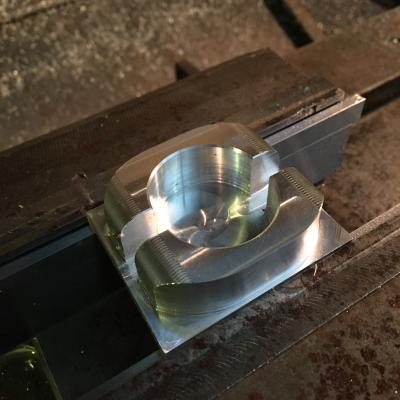

We have regularly published photos of our new MTB stem on our Instagram account, we can now officially launch the final version. This product is the first produced 100% by us due to the milling machine we bought earlier this year (even if the Fusion sprockets were almost produced by us...), we now manage the whole loop : CAD, CAM and machining ! To be honest, this project was very demanding and stressful, in fact stem production is much more complicated than a sprocket, requiring up to 6 different opérations and clamps (change of position of the stem in the machine), while a sprocket needs a single operation. A stem is a massive part in three dimensions (in comparison, a sprocket is a flat product, like two dimensions) with accurate dimensions (steerer tube and bar, several thread holes...etc.), geometry to be respected (ex : perpendicularity between steerer tube and bar). It requires thoroughness and rigor throughout the manufacturing process, without forgetting a need for specific cutting tools and also fixtures (wedges and interfaces for clamping the part, guide for tapping, etc.).

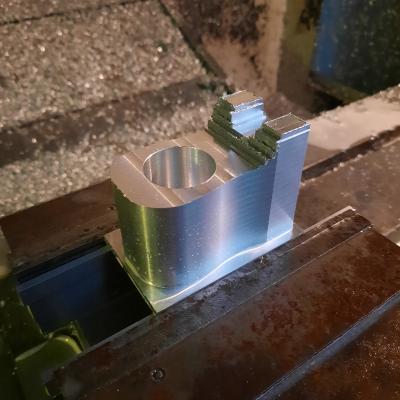

This stem is called "Noseball", beacause of these many surfaces produced by machining using a tool called "ball end" or "nose ball". For the explanation, these tools allow to obtain almost any surface / shape, by controlling the point of tangency between the spherical end of the tool and the surface to be produced, while dividing this surface / shape in very thin slices (from 0.01 to 0.1mm depending on the level of finish). It generates lots of tool back and forth movements, we love using these 3D operation carried out with ball end tool, opening up almost endless possibilities !

The Noseball stem will be available later this year, a first prototype has been tested on the boss' fat bike for two months, a small batch is also finished (including a black anodizing one) and is dispatched to three riders in order to approve the product. In terms of characteristics, the stem match 31,8mm bar, it's 50mm long and 0mm high, full stainless steel 6mm bolts, a total weight of 198grs and at least each stem is numbered by engraving (00 to 03).

This project is a success, it requires many hours of programming to achieve toolpaths allowing to obtain the expected end result, also many hours of machining and lots of (too much) reflection and questioning. We take this opportunity to thank several people who support us for this project : Pierre @ OP.N (FEA study, listening during the whole process of machining), Benoît @ LG Tech (many tips and support for cutting tools), Charles @ Versatil Motorcycle (supply for wedge and interface, guide for tapping), finally the riders who will ride and test the first stems were also source of support and motivation (Laurent @ boss' father, François @ ROD29, Pierre @ Royal shore).

Below, we present to you steps of machining (in chronological order) of the Noseball stem, from raw aluminum billet to the first prototype built up and also photos of the very beautiful black anodized version.